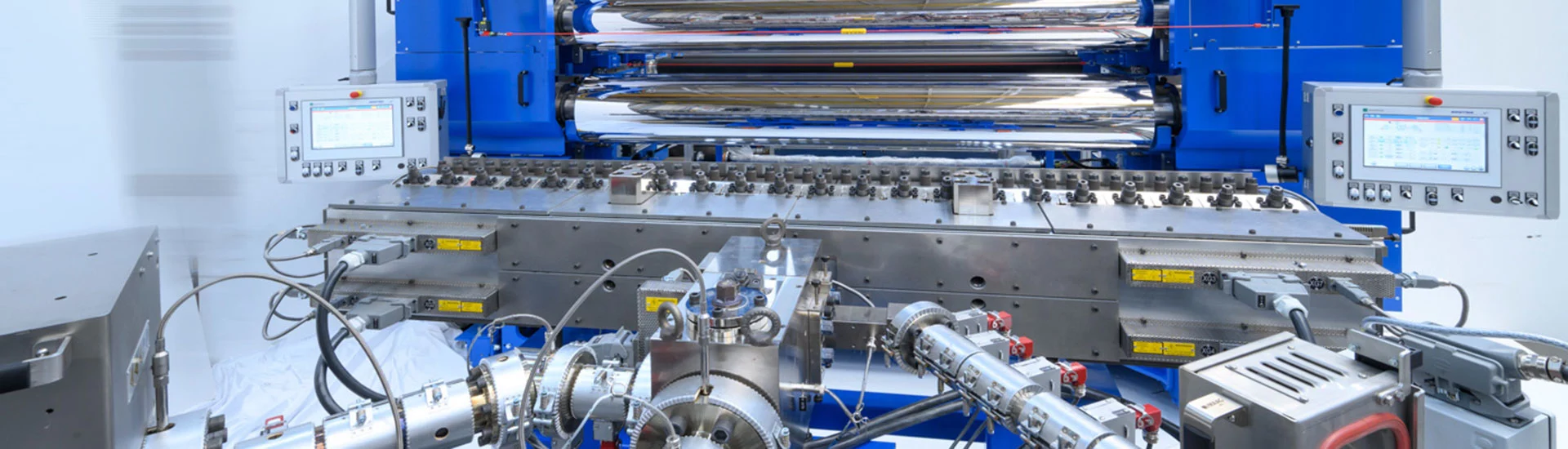

Your ideas. Our technology. - Test facility for high-quality flat films

With BREYER extrusion test lines, you can test your own materials and product ideas under real production conditions. Benefit from over 75 years of experience in the construction of precise extrusion lines for ultra-thin, low-tension flat films with the highest optical quality. Our flexible systems give you the certainty that your film solution will not only work - it will impress.

With our flat film line, you can also produce sheets up to 6 mm thick with the appropriate settings.

Technical data of the equipment

Material | PC, PMMA, PET-A, -C, PET-G, PLA, PS, COC, PES, ETFE, FEP |

Roll width | 1600 mm |

Line speed | up to 40 m/min |

Extruder | BREYER high-performance extruder ø 75mm x 36D, speed range up to 600 1/min, melt pump |

Screw selection | Various degassing screws as well as non-degassing and barrier screws |

Coextruder | Two BREYER coextruders ø 35x36D, with degassing, speed range up to 164 1/min, degassing screw, melt pump with 4.5 cm³/rev. |

Vacuumpump | Dry-running vacuum pump with pre-filters, 60 mbar, 140 m³/h |

Flat sheet dies | Film die, Sheet die, 3-channel-die, Widths 600 - 1550 mm |

Calender | Horizontal calender machine with three full-solid steel rollers (350/450/450 mm, mirror-polished surface), 3rd roller can be swiveled, servo-hydraulic roller gap adjustment with distance and pressure control. |

Lamination unit | For feeding substrates into the 1st or 2nd nip |

Additional rollers | Two FSR (flexible shell roll) rollers ø 350 mm, width 1600 mm, surface chrome-plated, mirror-polished 1x matt roller ø 450 mm, width 1600 mm, surface chrome-plated, matt Ra=2 µm 1x rubberized roller, ø 350 mm, width 1600 mm |

Thickness control system | Thermofischer brand with krypton emitter Kr 85 and strontium emitter Sr 95 |

Haul-off | Haul-off machine with 2 rubberized rollers, width 1600 mm, ø 260 mm, straight run or S-shaped wrap-around |

Masking unit | Protective film laminating device with 4 unwinding points, tension-controlled magnetic powder brakes, 3" winding shafts |

Cutting | Edge trimming device with 2 driven circular knives, edge strip winder |

Winder | 2-station winding system with winding turning machine and 30 m storage, max. winding width 1400 mm, max. winding ø 800 mm, 6" expansion shafts, max. winding speed 60 m/min. |

Further equipment | A cross-cutting saw, cross-cutting shears and saws for edge trimming are available for the extrusion of sheets up to 6 mm

|

BREYER – In the lead from the beginning.

![[Translate to Englisch:] BREYER Folienanlage](/fileadmin/_processed_/1/0/csm_Folienanlage-00-Optiflex_ae3f2f542d.jpg)