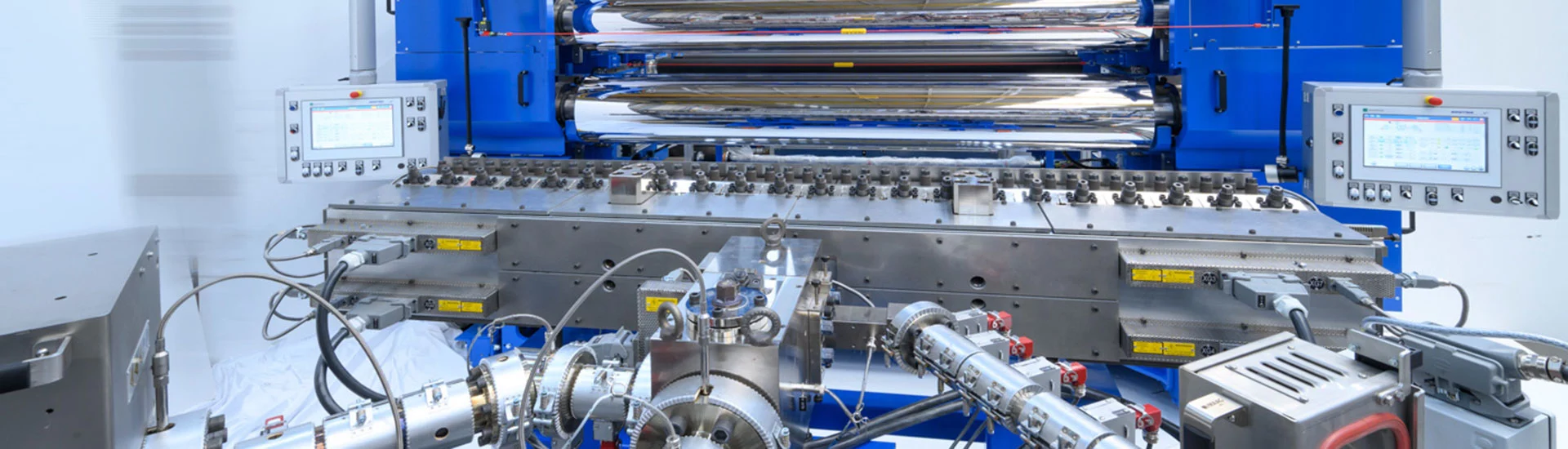

BREYER IONPress 800 calender for compacting coated electrode foil

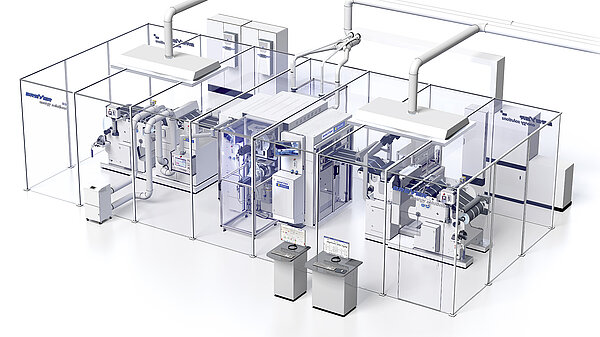

A range of technologies and process steps are required for the complete production of high-performance lithium batteries. BREYER has focused on the calendering process in this production chain.

During the calendering process, necessary properties such as increased power density, optimized electron transport, and improved contact between particles must be achieved.

With our calender, you can test your specific material and process specifications.

Material- and machine data (Anodes or cathodes)

Material data

Current conductor | Copperfoil, Aluminiumfoil |

Surface | continuously or intermittently coated, single-sided and double-sided coating |

Elektrode width | 100 – 700mm |

Coating width max. | up to 770 mm |

Coil weight max. | 800 kg |

Coil diameter max. | 800 mm |

Winding core lenght | max. 850 mm |

Maschine data

Line speed | up to 80 m/min (depending from electrode) |

Roller adjustment | hydraulically |

Gap adjustment | electro - hydraulic via monitor, |

Gap range | 0 – 30 mm |

Gap accuracy | ± 1 µm |

Max. power | max. 3800 N/mm |

Roller | Roll diamater: 800 mm Roll width: 800 mm Roll heating: up to 120°C Roller surface: Ra 0,02 – 0,03 µm |

Elektrode surface cleaning | in front of calender (both sides) |

Controled tension areas | 5 |

Roller cleaning | Scratcher |

Thickness control | Scanning confocal laser system |

Splice device | inside winder/rewinder |

Winder/rewinder | Coil weight: max. 800 kg, with automatic coil changer |

Control | Siemens , operated via touch screen |

Quality is the starting point for every success.