Perfect tubes, economically produced - test it for yourself

With BREYER test systems, you can develop and optimize tube packaging, e.g. for the cosmetics industry, under real production conditions. Experience how precise technology delivers consistent quality even at high speeds - for perfect design, convincing haptics and economical production, even with multi-layer structures.

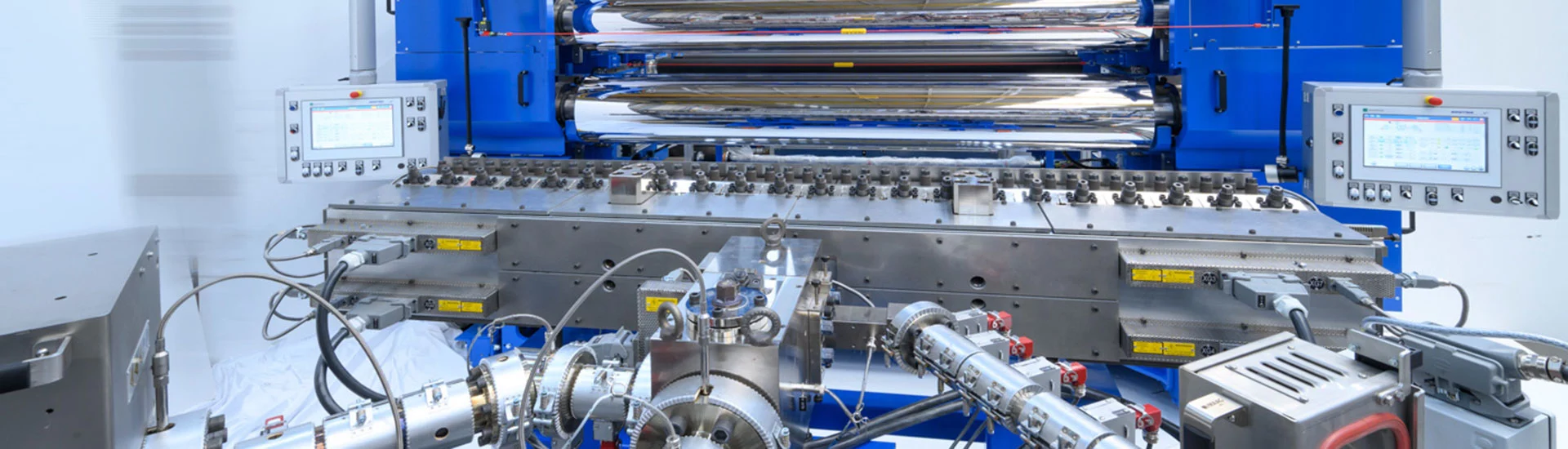

Extrusion line for the production of up to 5-layer cosmetic tubes

Materials | LDPE, LLDPE, HDPE up to 30%, CoPP, EVOH, PA. Further materials on request |

Produktion-Parameters |

|

Wall thickness | Range 0,25 – 0,80 mm Tolerance +/- 0,02 mm |

Length | 39,0 – 270,0 mm Tolerance +/- 0,5 mm |

Extrusion speed | up to 20 m/min |

Line configuration |

|

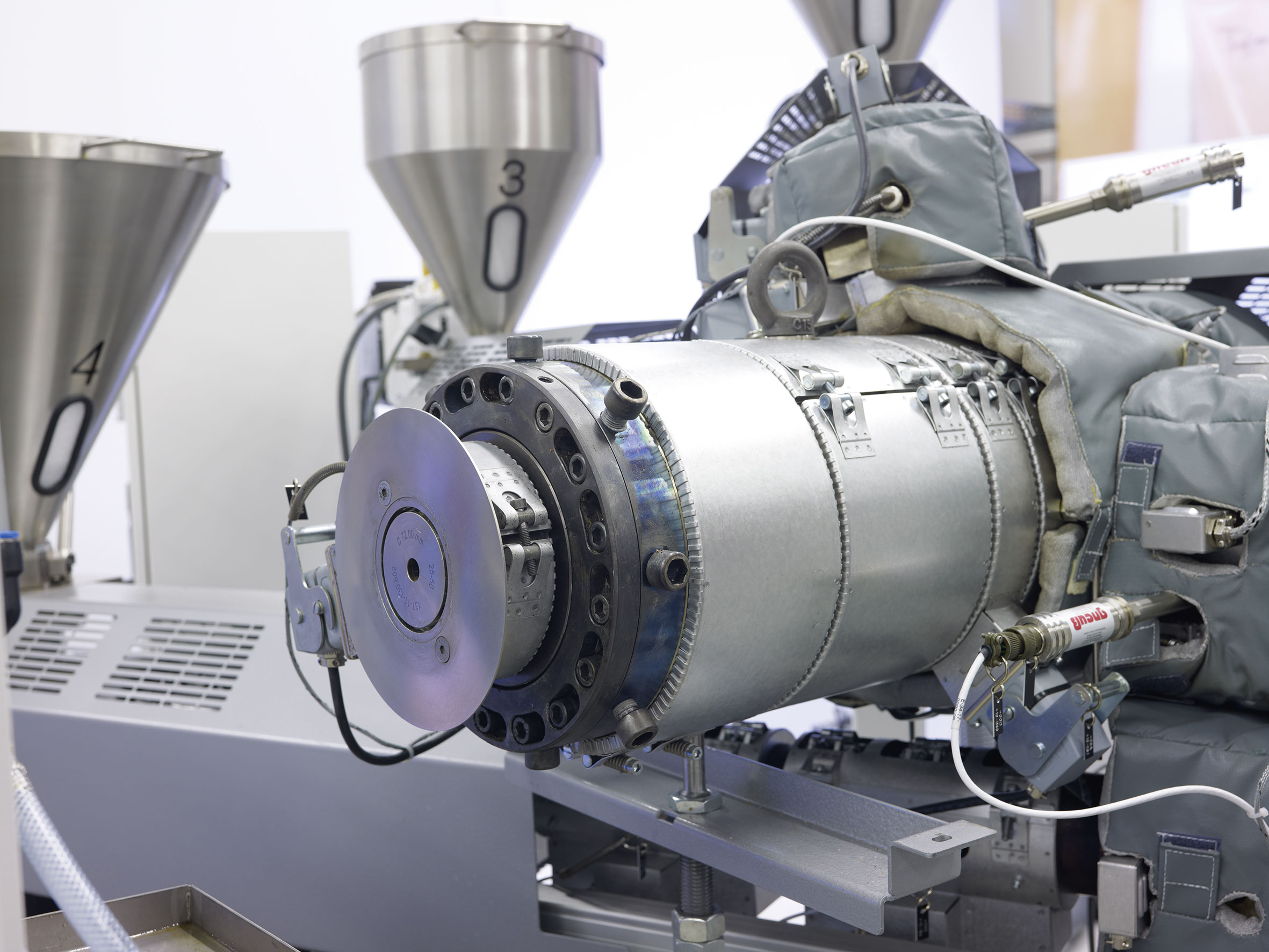

Single screw extruder | Ø 45, THE45 , Connecting flange to main extruder TAN 45 |

Single screw extruder | Ø 30, TCE30 Connecting flange to Co-extruder, TAN 30 |

Single screw extruder | Ø 30, TCE30 Connecting flange to Co-Extruder, TAN 30 |

Single screw extruder | Ø 45, TCE45 |

| Connecting flange to Co-Extruder, TAN 45 |

Multilayer die head | TRD |

Vacuum-Calibrator | TSK 25 |

Diameter control system | TDM |

Haul-off/Cuttingmachine | ECAM 120/150 |

Tools |

|

fot tube diameter | 22, 25, 30, 35 and 50 mm |

![[Translate to Englisch:] Tubenanlage ecoline Gesamtansicht](/fileadmin/_processed_/9/f/csm_Tubenanlage-ecoline01_0cc846c2c6.jpg)